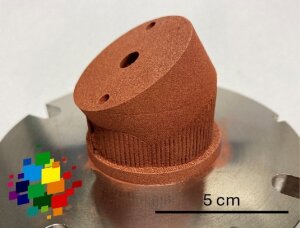

Additive manufactured mirror substrates made of copper with a purity of 99.7 %.

Image: Hagen KohlBased on additively manufactured optical substrates with internal cooling structures, a process chain for the resource- efficient production of high-performance optics will be developed. Highly efficient cooling close to the optically functional surface should open up new performance classes in the field of EUV metrology and laser material processing.

Subproject IAP:

Additive manufacturing of high-performance optical substrates with integrated cooling structures.

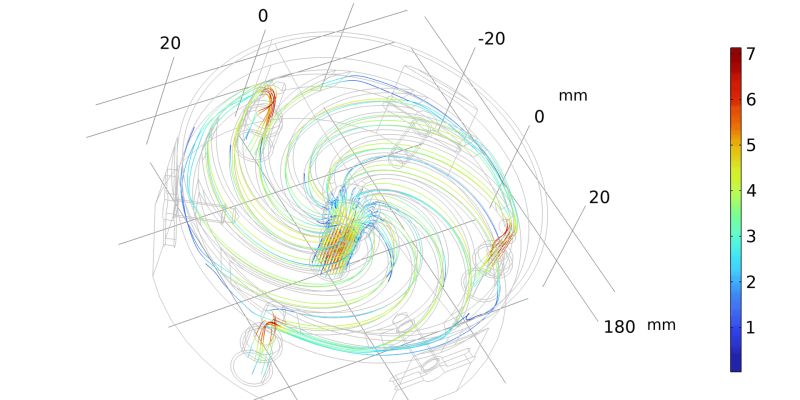

The project aims to develop an innovative process for the additive manufacturing of high-performance optical substrates with integrated cooling structures. This is achieved through collaboration with project partners to develop various cooling concepts near the optically functional layer. These concepts are evaluated through numerical simulations regarding thermally induced stresses and deformations. The implementation is carried out using laser-based additive manufacturing of OFHC copper (oxygen-free high-conductivity copper).

The focus of this subproject is on developing new manufacturing strategies to design the internal structures in such a way that efficient heat transfer to the cooling medium is ensured. The process development is supported by simulation models that represent the highly dynamic processes during manufacturing. Finally, the manufactured samples will be examined for their material properties and cooling performance and further functionalized by the consortium to meet the requirements of real-world applications.