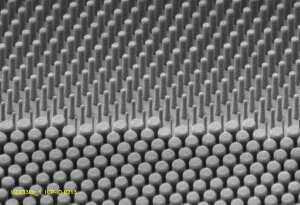

Fig. 1: SEM image of an effective index grating.

Image: IAP (University Jena)A diffractive grating is a periodic structure that splits the incoming light into several beams, called diffraction orders. The intensity distribution of the diffracted light depends on the grating profile and the wavelength. With the usage of structures smaller than the wavelength, effective index profiles can be designed that provide a high efficiency for the desired orders (Fig. 1).

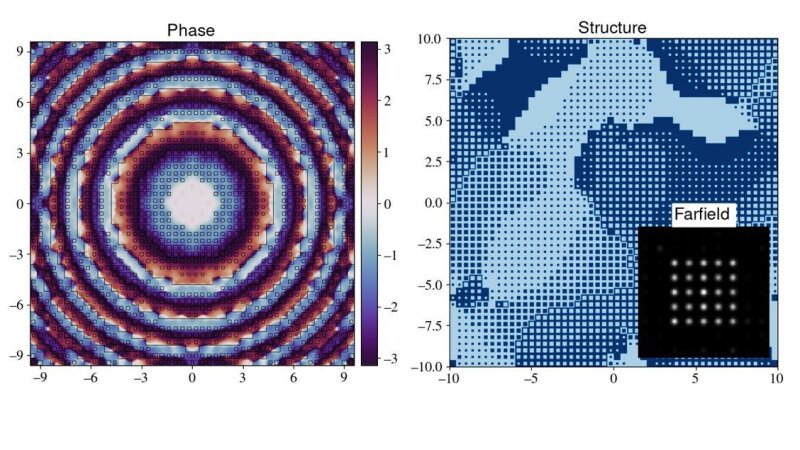

A diffractive optical element (DOE) can manipulate the amplitude and phase profile of the incoming light. For example, a metalens can be created with a high focusing efficiency (Fig. 2). With computer generated holograms (CGHs) almost arbitrary intensity distributions can be created from the incoming light, e.g., a beam splitter (Fig.3). The individual structures can be designed by rigorous simulation methods (FDTD, RCWA) while their arrangement relies on paraxial algorithms (IFTA). With semi-rigorous methods (BPM) the performance of an entire element can be analyzed and optimized. The fabrication of the elements utilizes e-beam lithography and refractive ion beam etching. The effective index structures can be fabricated by only one lithography and etching step.

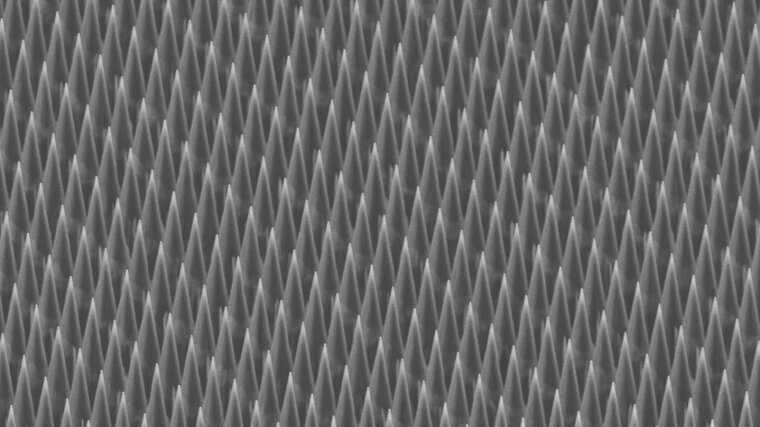

Our modern lithographic micro-structuring capabilities allows to apply these concepts also for applications at extreme wavelengths in the deep-ultraviolet- and far-infrared spectral region. Examples are sub-wavelength structure based anti-reflection structures in exotic materials such as Diamond (Fig. 4) or transmissive diffractive diffusers for the EUV at 13.5nm wavelength (Fig. 5).

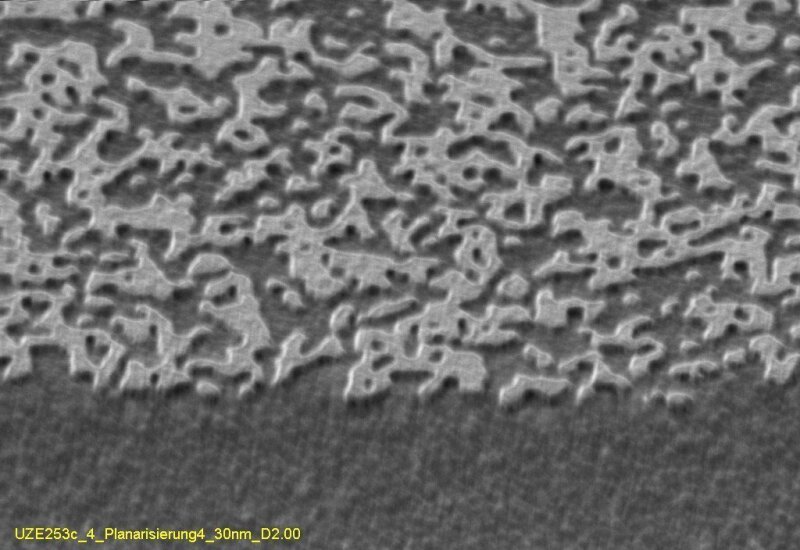

Fig. 5: Transmissive diffractive diffusor (Mo structure on a 100nm thick Si3N4-membrane) for 13.5nm wavelength.

Picture: IAP (University Jena)